What are the main types of pharmaceutical manufacturing equipment? Pharmaceutical manufacturing equipment is classified into two core categories: Processing Equipment for drug formulation (mixing, granulating, pressing) and Packaging Equipment for protection and distribution (blistering, bottling, cartoning). Modern production lines prioritize automation and GMP compliance to ensure dosage accuracy, prevent contamination, and maximize output efficiency.

Processing equipment is the heart of the factory. These machines handle the physical and chemical transformation of Active Pharmaceutical Ingredients (APIs) into safe, consumable forms.

Solid forms like tablets and capsules are the most common delivery methods. Precision here is vital for patient safety.

Tablet Press Machine: High-speed rotary systems that compress granulated powder into tablets with uniform weight and hardness.

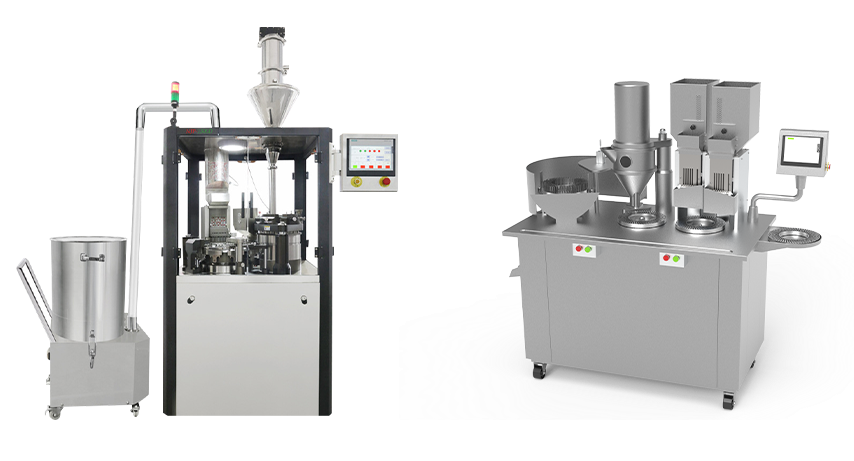

Capsule Filling Machine: Available in fully automatic or semi-automatic models to fill hard gelatin capsules with powders, pellets, or liquids.

Tablet Coating Machine: Applies a thin, protective film to tablets to control drug release, mask bitter tastes, or improve shelf life.

Capsule/Tablet Polisher: Uses rotating brushes and vacuums to remove excess dust and static, ensuring a clean, pharmaceutical-grade finish.

Before a drug can be pressed or filled, the raw materials must be conditioned for optimal flow and consistency.

Fluid Bed Dryer (FBD): A critical machine that uses heated air to suspend wet granules, ensuring rapid and uniform drying without damaging heat-sensitive ingredients.

High-Shear Granulator: Uses high-speed impellers to turn fine powders into dense, uniform granules, preventing ingredient separation.

Powder Mixing and Blending: V-type or Ribbon blenders ensure that APIs and excipients are perfectly homogenized for consistent dosing.

Vibration Sieve: Screens powders and granules to ensure only the correct particle sizes move forward in the production line.

Complex drugs like oils, vaccines, or creams require specialized containment and environmental control.

Softgel Encapsulation Machine: Integrates gelatin ribbon preparation and precision injection to create seamless, leak-proof soft capsules.

High-Pressure Homogenizer: Reduces particle sizes to the micron level to create stable emulsions for injectable or oral liquids.

Freeze Dryer (Lyophilizer): Removes moisture via sublimation under vacuum, preserving the potency of vaccines and biological proteins.

Packaging is more than just a container; it is a barrier against moisture, light, and biological contamination.

This equipment handles the material that touches the medicine directly.

Blister Packing Machine: Forms cavities in plastic or aluminum film, inserts the product, and seals it to create tamper-evident unit doses.

Liquid Filling and Bottling Line: Uses high-precision nozzles to fill bottles or vials with exact volumes, preventing waste of expensive APIs.

Tube Filling Machine: Fills and seals tubes for ointments and creams using heat-sealing or mechanical folding technology.

Final-stage machines ensure the product is ready for the pharmacy shelf and meets all regulatory tracking requirements.

Automatic Cartoner: Automatically folds leaflets, inserts the product (bottles or blisters), and seals the outer box with high efficiency.

Induction Sealer: Uses electromagnetic fields to create a hermetic foil seal on bottle mouths, ensuring the product remains airtight.

Labeling Equipment: Applies precise, compliant labels to containers, often integrating QR codes for batch tracking and anti-counterfeiting.

Tablet & Capsule Counter: Uses advanced optical sensors to count solid doses with 100% accuracy before bottling.

To help you choose the right configuration for your facility, here is a breakdown of essential equipment features:

| Machine Category | Automation Level | Core Application | Key Technical Focus |

| Capsule Filler | Semi / Fully Auto | Solid Dosage | Weight precision & high output |

| Fluid Bed Dryer | Fully Auto | Granulation | Heat control & drying uniformity |

| Tablet Press | Fully Auto | Tablet Forming | Hardness & thickness consistency |

| Blister Packer | Fully Auto | Primary Packaging | Hermetic sealing & drug integrity |

| Softgel Machine | Fully Auto | Oil/Liquid Filling | Encapsulation precision & cooling |

Selecting the right equipment is a balance between high-speed output and strict GMP (Good Manufacturing Practice) compliance. At LTPM, we understand that every milligram counts.

Our machinery is designed with a "Quality by Design" (QbD) approach, featuring easy-to-clean surfaces to prevent cross-contamination and intelligent PLC control systems for real-time data monitoring. From standalone Fluid Bed Dryers to complete Turnkey Softgel Production Lines, we provide the precision your pharmaceutical business demands.

Are you looking to increase your production capacity or transition to a fully automated manufacturing workflow?

Contact LTPM Today to speak with our technical engineers. We can help you customize a production line that meets your specific output goals and international regulatory standards.

We use cookies to enhance your browsing experience and protect your privacy. Please read our privacy policy for more information.