Capsules are solid dosage forms primarily for oral use. They are prepared by filling powdered drugs and suitable excipients into empty shells. The capsule shell effectively masks undesirable tastes or odors and also protects the contents from external moisture and light.

Capsules are divided into two main categories: Soft Gelatin Capsules and Hard Gelatin Capsules.

This guide provides a comprehensive comparison of these two types, highlighting their key differences in structure, composition, applications, and manufacturing processes to aid in the appropriate selection of capsule type for specific pharmaceutical formulations.

A softgel is a sealed, single-piece capsule specifically designed to encapsulate liquid or semi-solid fills. The outer shell, typically composed of gelatin, water, a plasticizer (such as glycerin or sorbitol), and potentially opacifiers, colorants, or preservatives, encloses the inner formulation. Active Pharmaceutical Ingredients (APIs) can be present in both the shell and the fill.

The inner content most commonly consists of oil-based solutions or suspensions, as water-based formulations would dissolve the gelatin shell. Upon ingestion, the gelatin shell dissolves rapidly in the gastric fluid, usually within minutes, releasing the drug contents for absorption.

Provide a patient-friendly dosage form for administering unpalatable or oily liquids.

Effectively mask disagreeable odors or tastes, offering a neat appearance and easy ingestion.

Can facilitate rapid drug release and dispersion in the stomach.

Offer high manufacturing reproducibility.

Are particularly beneficial for lipid-soluble drugs at low doses.

Are a superior alternative to tablets for encapsulating water-insoluble liquid drugs.

Can be coated for delayed, enteric, or sustained release.

Require specialized and expensive manufacturing equipment.

Can present stability challenges for highly water-soluble or hydrolyzable compounds.

Have limitations on compatible excipients due to interactions with gelatin.

The shell's plasticity and elasticity are key to its manufacturing. The liquid or semi-solid fill must meet specific requirements: water content should not exceed 5%, volatile solvents (alcohols, ketones, esters) should be avoided as they can dissolve the shell, and aldehydes should be avoided as they cross-link with gelatin. The pH of the fill must be controlled between 2.5 and 7.5 to prevent hydrolysis of the gelatin.

Two primary methods are used:

Dropping Method: A double-layer nozzle simultaneously discharges the warm shell liquid from the outer orifice and the drug fluid from the inner orifice. The combined droplet is then cooled and solidified in a column of immiscible cooling liquid.

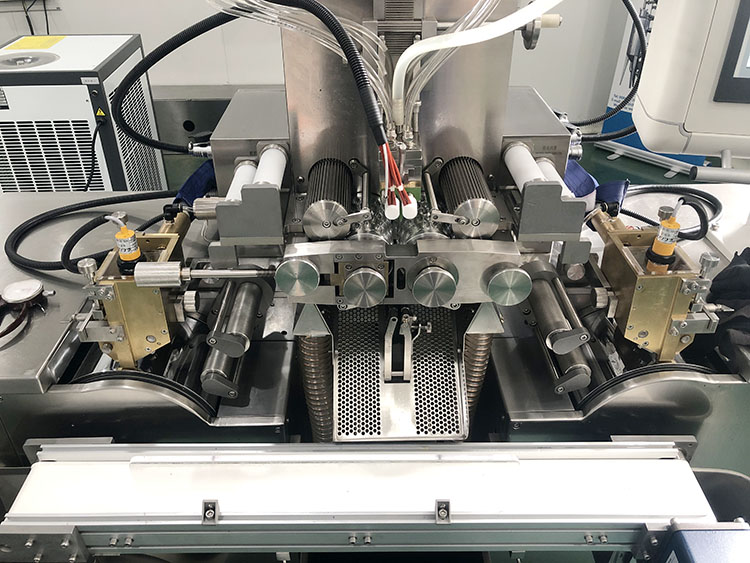

Compression Method: Two continuous gelatin ribbons are formed. The drug fluid is injected between them, and the ribbons are then pressed together into molds by rotating dies, which cut and seal the capsules.

Hard gelatin capsules consist of two pre-formed, cylindrical sections: a body and a slightly larger cap. They are designed to enclose dry formulations such as powders, granules, pellets, or even small tablets. The manufacturing process involves filling the body and then sliding the cap over it to close the capsule, often employing a mechanical press to ensure a secure join.

Often exhibit higher bioavailability than tablets.

Offer great formulation flexibility, allowing for the filling of powders, granules, pellets, mini-tablets, and semisolids.

Beads for modified-release are not damaged during the filling process (as no compression is involved).

Ideal for use in clinical trials and early drug development due to their flexibility.

Fewer suppliers for empty shells compared to other dosage form components.

Can potentially stick in the esophagus, causing local irritation.

Generally not suitable for highly soluble salts (e.g., bromides, chlorides).

Typically more expensive to manufacture than tablets.

Filling and sealing processes are generally slower than the integrated manufacturing process of softgels.

Manufacturing involves sourcing empty shells, preparing the fill formulation, filling the bodies, and sliding the caps on to close the shells. The selection of appropriate capsule fillers is crucial to ensure optimal flowability and consistent dosing. The shells are made from similar components as softgels but contain much less plasticizer, making them rigid.

Gelatin shells are sensitive to humidity (hardening when dry, softening when wet) and can react with aldehydes. Therefore, strict control of storage conditions is necessary. To overcome these limitations, plant-based shells made from materials like hydroxypropyl methylcellulose (HPMC) or starch are now widely used as alternatives. These vegetarian capsules are often more stable, less variable, and can withstand higher temperatures.

| Feature | Soft Gelatin Capsules (Softgels) | Hard Gelatin Capsules |

|---|---|---|

| Structure | One-piece, hermetically sealed | Two-piece (body and cap) |

| Content | Liquids, semi-solids, pastes | Dry powders, granules, pellets |

| Shell | Higher plasticizer content, flexible | Lower plasticizer content, rigid |

| Shape | Oval, round, tubular, unique shapes | Cylindrical |

| Dissolution | Typically faster release | Slightly slower release |

| Manufacturing | Content is encapsulated during shell formation in one process | Empty shells are pre-made, then filled and joined in a separate process |

The choice between soft and hard gelatin capsules is fundamentally guided by the physical state of the active ingredient and the target product profile.

Softgels are uniquely suited for liquid and semi-solid formulations, leveraging their one-piece, sealed design to excel in enhancing the bioavailability of lipid-soluble compounds and providing an exceptional barrier against oxygen.

Hardgels, on the other hand, offer unparalleled flexibility for solid formulations, serving as an ideal platform for multi-particulate systems, combination products, and rapid prototyping in drug development. Their two-piece design facilitates a wider range of fill types but offers a less impermeable seal than softgels.

In summary, the choice between soft and hard gelatin capsules depends on the API's properties, target release profile, and production requirements. Softgels excel in encapsulating liquids and enhancing bioavailability, while hardgels offer superior flexibility for solid formulations.

At LTPM, we deliver high-performance pharmaceutical machinery solutions, specializing in solid and liquid dosage processing equipment. To explore advanced capsule formulation and manufacturing solutions, Feel free to Contact us today.

We use cookies to enhance your browsing experience and protect your privacy. Please read our privacy policy for more information.