- Fully Automatic Capsule Filling Machine

- Semi Automatic Capsule Filling Machine

- Liquid Capsule Filling Machine

- Capsule Polishing Machine

Why Choose Liquid Encapsulation?

Overcome the limitations of traditional powder capsules. Liquid encapsulation enhances the bioavailability of active ingredients, ideal for poorly soluble compounds, oils, and sensitive formulations. It allows for innovative product development in pharmaceuticals, nutraceuticals, and high-end cosmetics, offering superior consumer experiences and product stability.

Specification

| Model: | LiqPro-300 |

| Maximum capacity | 18,000 capsules/hour |

| Sealable capsule filling | Solution,suspension,microemulsion |

| Mold hole number | 6 holes |

| Environmental reguirements | Room temperature around 20C, humidity 40% -55% |

| Voltage | Three-phase 380V/220V 50Hz |

| Compressed air | 0.6Mpa |

| Weight: | 2300KG |

| Dimensions: | 3800*900*1900mm |

Primary Applications

Pharmaceutical: Pediatric doses, lipid-based drug delivery systems (LDDS), highly potent APIs (HPAPIs), and taste-masking of bitter compounds.

Nutraceutical & Functional Foods: Fish oils (Omega-3), CoQ10, vitamin E, botanical extracts, probiotics in suspension, and nutritional supplements.

Cosmetic & Personal Care: Premium beauty oils, serums, and other innovative cosmetic ingredients for oral beauty products.

Engineer Your Production Line for Excellence

Our engineered systems seamlessly combine automated capsule handling, precision filling, and reliable sealing in one efficient, integrated line. This end-to-end design simplifies your process while delivering unmatched accuracy and leak-proof security for your most demanding formulations. Speak with our engineering team today by info@ltpmchina.com to find the perfect system for your production requirements.

Product video

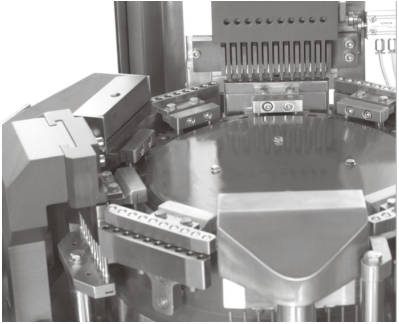

How Does a Liquid Capsule Filling Machine Work

Core Advantage

Ultra-Precise Dosing

Achieve remarkable fill weight accuracy within ±1-2% using our advanced servo-driven pump and dosing systems (e.g., precision ceramic pumps), ensuring consistent dosage in every single capsule.

Guaranteed Leak-Proof Sealing

Our proprietary sealing technology, including reliable banding or liquid sealing methods, hermetically seals the capsule cap and body, preventing leakage during handling, storage, and transport, thereby extending product shelf life.

Exceptional Versatility

Effortlessly handle a wide range of substances: from oils, solutions, and suspensions to emulsions and pastes. Quick-change parts and tooling allow for fast transitions between different capsule sizes (#000 to #4) and types (gelatin, HPMC, pullulan).

GMP & FDA Compliance

Constructed from 316L or high-quality 304 stainless steel with polished surfaces, our machines are designed for easy cleaning and sterilization. They are built to meet stringent hygienic standards and facilitate validation processes.

Scalable Productivity

From flexible R&D and pilot-scale models to high-speed production lines capable of outputting over 30,000 capsules per hour, we have a machine to fit your throughput requirements without compromising on quality.

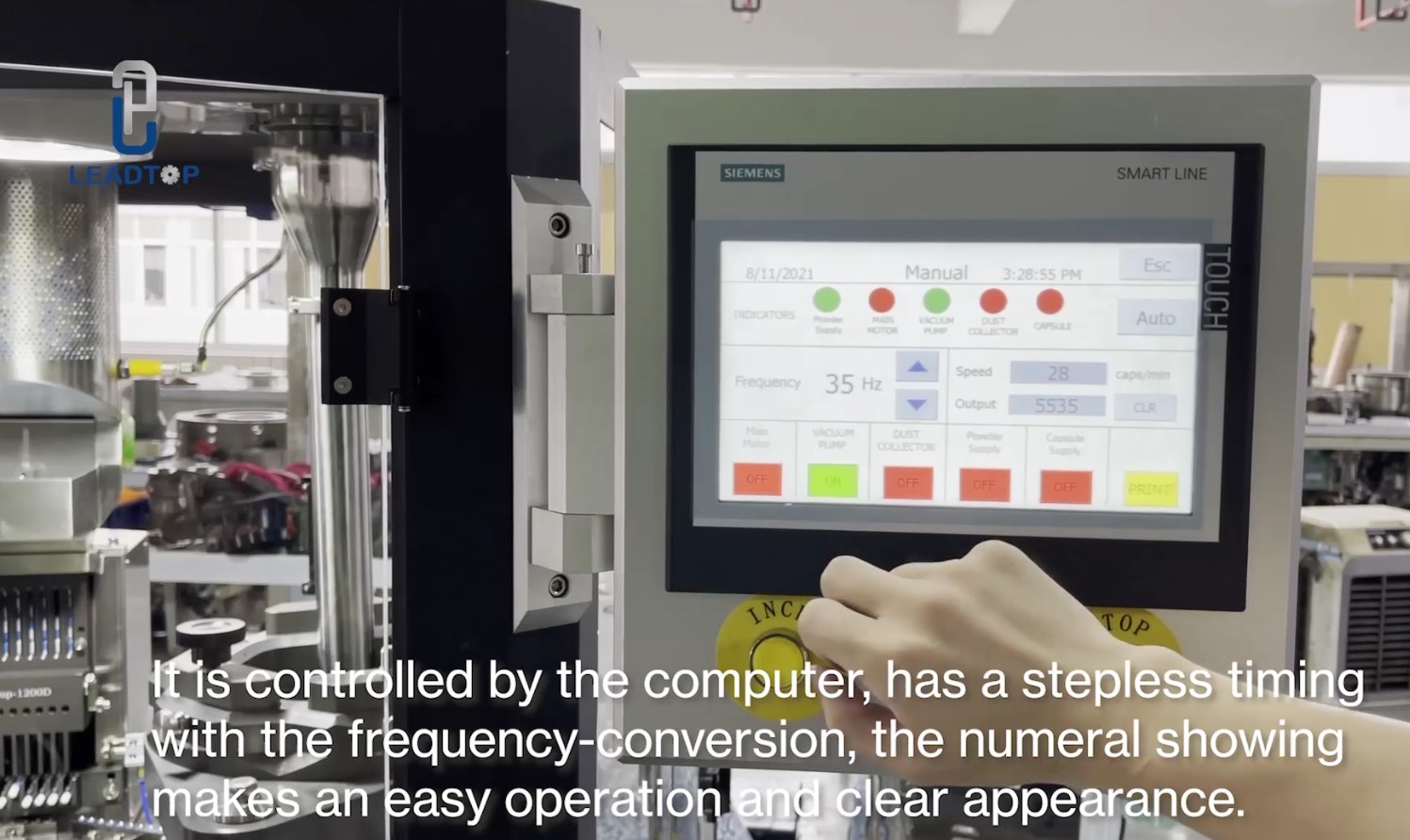

User-Centric Automation

Featuring an intuitive HMI (Human-Machine Interface) with recipe management, automated CIP (Cleaning-in-Place) options, and comprehensive data logging for full production traceability. Real-time monitoring systems detect and reject defective capsules automatically.

FAQ

-

What is a Liquid Capsule Filling Machine?

The liquid capsule filling machine is a highly precise and versatile equipment designed for encapsulating liquid, semi-liquid, or gel formulations into soft or hard capsules.

-

What are the advantages of a liquid capsule filler compared to a traditional powder machine?

A liquid encapsulation system provides key advantages for modern formulations. It significantly enhances the bioavailability of poorly soluble drugs by delivering them in a solubilized state. Liquid dosing also offers superior precision, with fill weight accuracy within ±2%, and creates a completely dust-free environment, essential for worker safety and potent compound handling. Furthermore, it unlocks new possibilities for formulating with oils, extracts, and other liquid-based active ingredients. For a complete overview of all our encapsulation technologies, explore our range of capsule filling machines.

-

What types of formulations can this machine handle?

Our liquid capsule fillers are engineered to accurately dose a wide range of formulations, including solutions, suspensions, microemulsions, and even hot-melt substances, into both gelatin and plant-based capsules.

-

How do you prevent the finished capsules from leaking?

The machine ensures leak-proof integrity through a combination of highly precise volumetric filling to avoid overfills and a subsequent proprietary sealing process that hermetically seals the capsule cap to the body.

-

Do your machines support vegetarian (plant-based) capsules?

Absolutely. Our equipment is fully compatible with non-gelatin capsules, including those made from HPMC and pullulan, with adjustable settings to gently and reliably handle their different material characteristics.

-

Is this equipment suitable for high-potency active ingredients?

Yes. The closed-loop filling system and cleanable design minimize the risk of operator exposure and cross-contamination, making it an ideal choice for handling highly potent compounds in a contained environment.

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China